Page 1 of 1

New Life for an Old Bench Grinder

Posted: Fri Aug 04, 2023 4:18 pm

by greybeard

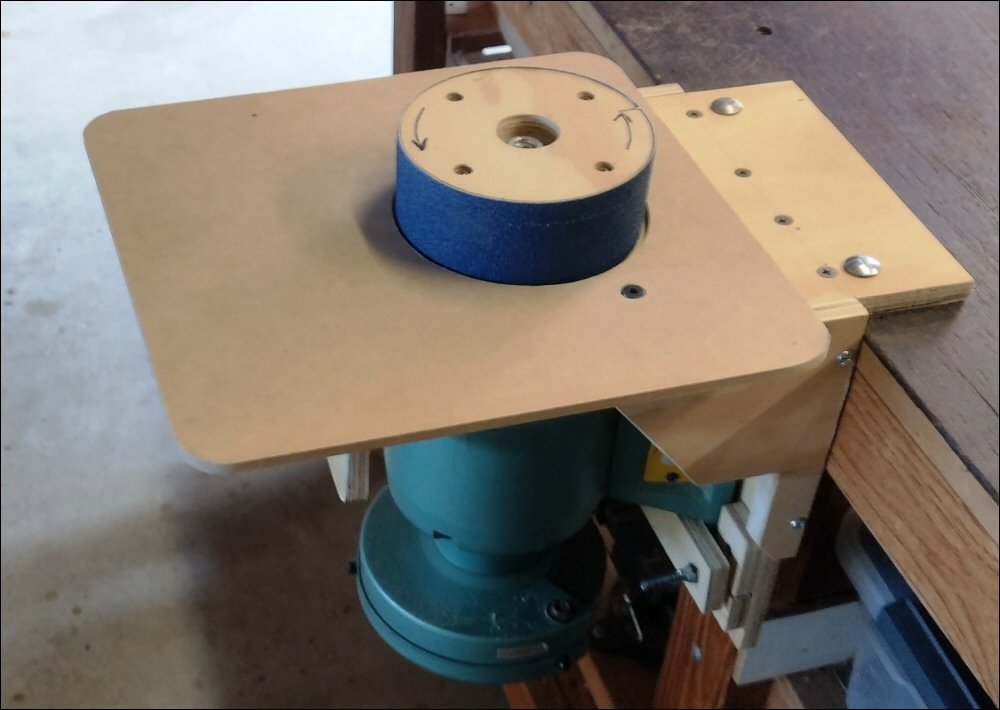

After replacing the on/off switch in an old six inch bench grinder I decided to use it to make a drum sander.

Fortunately I had a piece of ½” plywood that was big enough to make the grinder holder as well as two laminated sanding drums.

I will now be able to shape handle / risers on this machine instead of using the wheel of the lamination grinder.

With the removable top in place it allows for full width sanding when using the 5” drum with a 2” depth. The smaller drum has a 2” diameter and 3” depth. I still need to design a 1” diameter drum.

The unit can be mounted horizontally on the work bench if needed.

Daryl.

- 2 Inch Drum.jpg (118.32 KiB) Viewed 6619 times

- 5 Inch Drum.jpg (84.93 KiB) Viewed 6619 times

Re: New Life for an Old Bench Grinder

Posted: Fri Aug 04, 2023 5:58 pm

by metalhead

That's a good idea. How do you change drums?

Re: New Life for an Old Bench Grinder

Posted: Sat Aug 05, 2023 9:35 am

by hardgainer

now that is a great idea.

Re: New Life for an Old Bench Grinder

Posted: Sun Aug 06, 2023 12:57 pm

by greybeard

metalhead wrote: ↑Fri Aug 04, 2023 5:58 pm

That's a good idea. How do you change drums?

The sanding drums can be changed in the same manner as with a grinding wheel. Undo the retaining nut slip the drum off the shaft put the other drum on and replace the retaining nut.

Changing the sand paper may be a little more difficult.

The 5” drum has a rim speed of 3800 feet per minute so contact adhesive was used. The leading edge, approximately ¼” of the sandpaper without adhesive is put into the narrow slot across the drum. The remaining sandpaper and drum have contact adhesive applied and when the adhesive has tacked off the sandpaper is carefully rolled around the drum.

Eventually when the sandpaper needs replacing I may have to use a heat gun to soften the adhesive.

The 2” drum has a rim speed of 1454 feet per minute and as it will be using finer grit sandpapers I have used two sided tape. The leading edge is angled across the drum. So far the two sided tape has not come adrift.

The 5” drum must be fractionally out of round as more wood dust was retained by the sandpaper near the join and directly opposite. The high rim speed must negate this slight issue as the curve in the handle is nice and even. The fadeouts will be finished by hand with 40 grit sandpaper on the curved end of the sanding stick.

The next task is to make a dust extractor shroud as sanding dust got blown all over the place.

Daryl.

*

- Drum.jpg (114.53 KiB) Viewed 6566 times

- Handle.jpg (34.23 KiB) Viewed 6566 times

Re: New Life for an Old Bench Grinder

Posted: Sun Aug 06, 2023 12:57 pm

by greybeard

The site went off line whilst submitting a reply, saved as a draft and somehow got duplicated when back on line.

Daryl.

Re: New Life for an Old Bench Grinder

Posted: Mon Aug 07, 2023 5:31 pm

by Stickbow Hunter

Good setup there.

Jeff

Re: New Life for an Old Bench Grinder

Posted: Tue Aug 08, 2023 12:03 pm

by greybeard

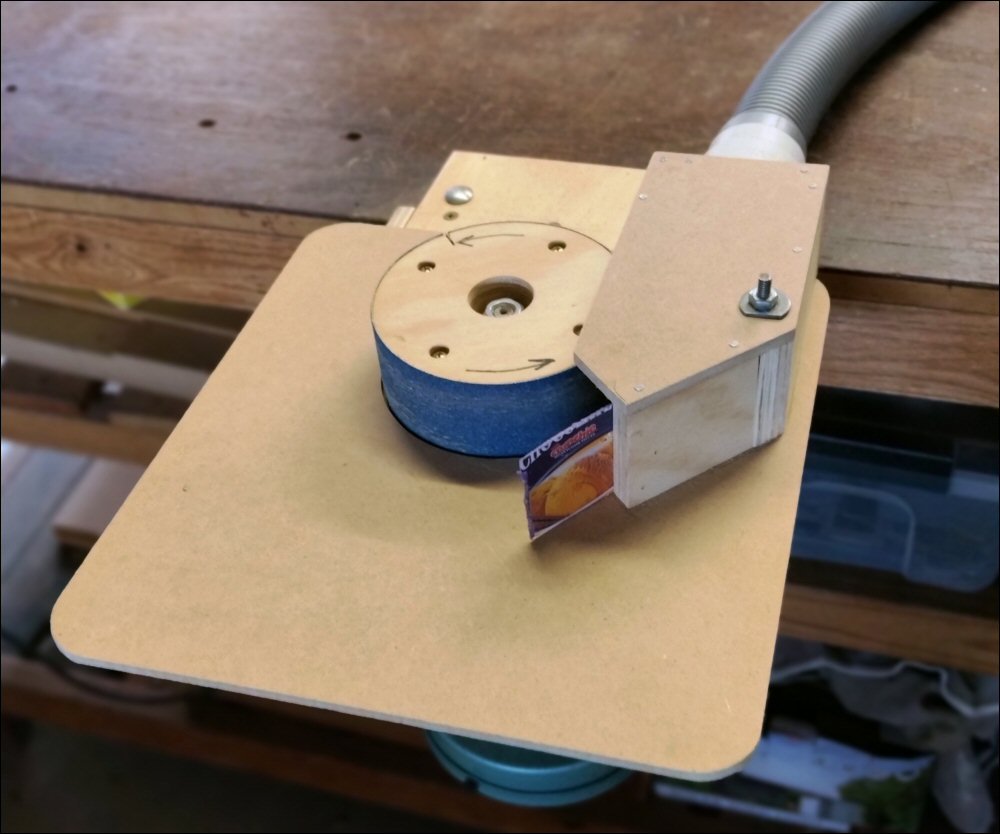

The dust extractor shroud was made from off cuts and appears to be very efficient.

Daryl.

*

- Extractor Shroud.jpg (96.7 KiB) Viewed 6509 times

Re: New Life for an Old Bench Grinder

Posted: Wed Aug 09, 2023 10:29 am

by Stickbow Hunter

Should work a treat.

Jeff

Re: New Life for an Old Bench Grinder

Posted: Sun Aug 20, 2023 12:06 pm

by greybeard

This is the first handle off the new grinder set up and the unit worked better than expected.

The Brigalow was harvested in the Kingaroy area about two years ago.

Daryl.

*

- Brigalow Handle.jpg (45.83 KiB) Viewed 6309 times

Re: New Life for an Old Bench Grinder

Posted: Thu Aug 24, 2023 10:49 am

by Stickbow Hunter

Very nice!

Jeff